HOW RECYCLING AND REFINING MACHINES WERE BORN

Not knowing the chemistry of gold and being an architect

has been an important factor in my industrial design of machines.

The significance of these machines, which I designed, drew, and manufactured myself,

lies in the fact that the refinement process is odorless and smokeless.

Since 1975, we continue to manufacture machinery with chemical process innovation and new designs.

● In 2022, we designed a highly effective new model of scrubbers that eliminates the use of caustic in the wash water, and separates NOx into nitrogen and oxygen. As a result, we produced a system that is smaller in size, can operate completely without a chimney, and does not require changing the usage water.

● 2016 - I developed the runnerless casting system again to be used in jewelry industry and applied for a patent.

● 2015 - I patented the highly novel and revolutionary jeweler's polishing machine. Currently, manufacturing schedule of this machine is in progress.

● 2009 - I started marketing the machinery I manufactured on a global basis and realized over hundreds of installations in 60 countries.

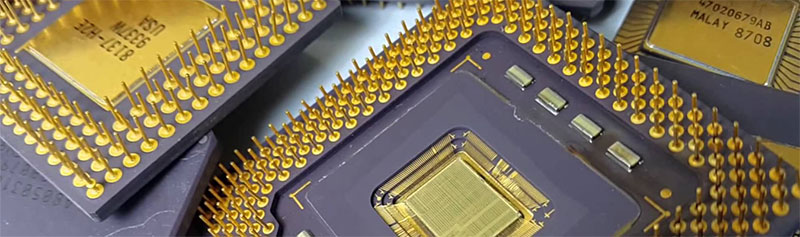

● I designed and manufactured machinery that recycled precious metals from electronic waste and catalytic converters in 2001.

● 1996 - I designed and manufactured a complicated piece of machinery that operated in short circuit and neutralized acid vapors, and particularly worked on aqua regia to produce 999.9 gold purity, instead of using quartering method as the refining system. This machine recycles precious metals such as gold, silver, platinum, palladium and rhodium without generating any odors and exhaust gases.

● 1987 - Improving the recycling systems that were inventions of my own, I manufactured the current state of recycling and refining machine.

● 1985- I opened up the first grade detection workshop that provided rapid carat control by potentiometric titration. This procedure decreased the 5-hour time period then required for grade control, to only 1 hour.

● 1983 - I built a decanter centrifuge that enabled separation of recycling sludge from the acid.

● 1979 - I established the first chemical recycling facility in the industry that utilized aqua regia, and increased the recycling efficiency up to 98% accordingly. Before 1979, recycling was performed solely by cupellation/melting method, and recycling efficiency of this method -particularly for recycling of polishes- was within the range of 25-30%.

● 1975 - While working as an architect during the year of 1975, I also established my chemistry laboratory to produce gold and silver from anode slime.

Products that I invented and developed

● Acidic hoodless precious metal tube emptying system

● Blasting machine that recovers gold in 100%.

● Incineration furnace that enables incineration of waste and recycled matter without generation of exhaust gases and losses.

● Drying machine for hollow products.

● Filters that enable discharge of acid vapors and effluents in compliance with environmental regulations.

● Gold plating system

● Gold chemicals, gold cyanide, silver cyanide, gold chloride, gold amalgam (tombac)

● Platinum, palladium and rhodium recovery systems built from catalytic converters

● Electronic waste recycling systems